FMEA - Failure Mode and Effects Analysis

Risk Management

Actions to Reduce Risks

Review & Sustainability

Controlling & Monitorship

More emphasis should be placed on preventive quality procedures than on real-time control techniques, particularly throughout the production process. The risks should be evaluated with foresight activities for the processes that span from acquiring raw materials and semi-finished goods to delivering the product to the ultimate consumer, and at the same time, actions that eliminate the risk or lessen its impact should be performed.

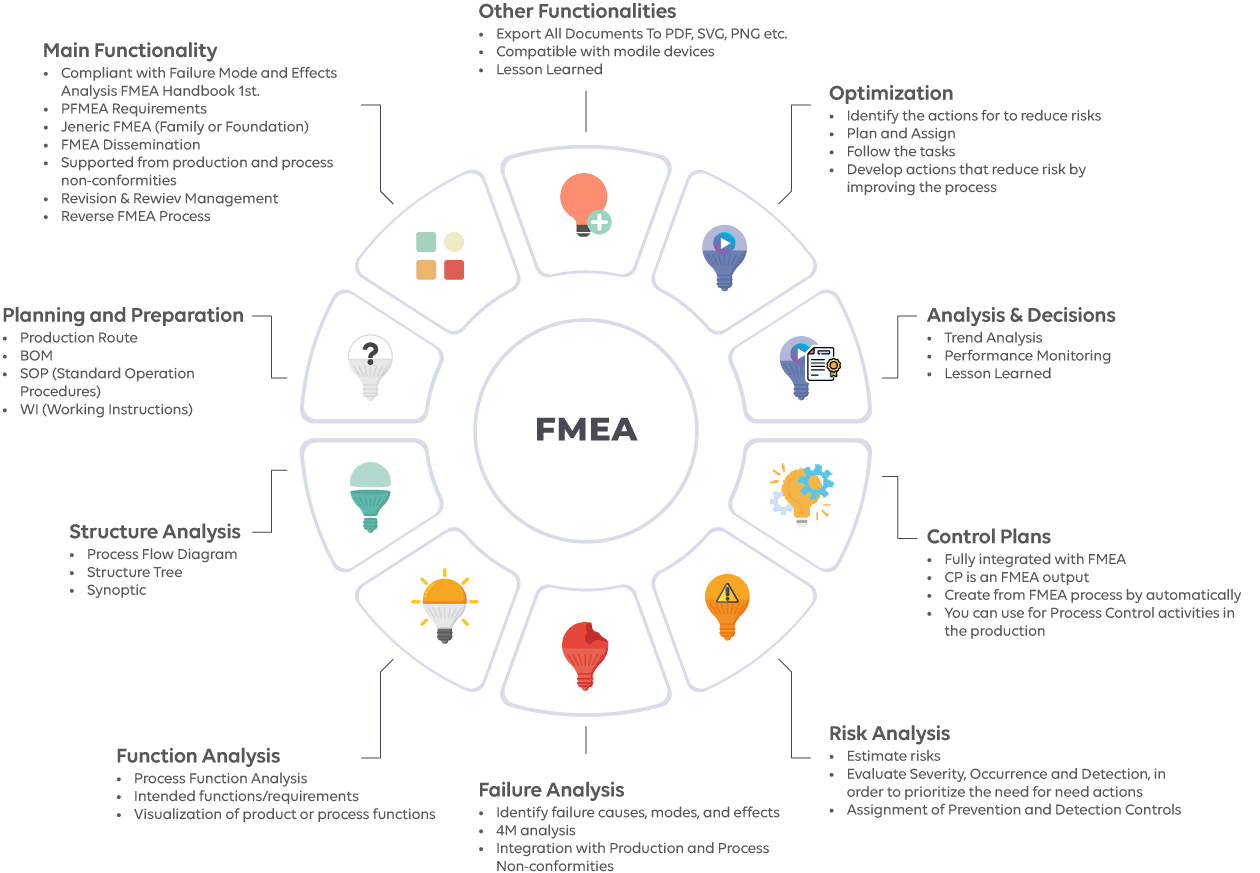

The FMEA (Failure Mode and Effects Analysis) is an analytical method of preventive quality management in product and process development. It is used to identify and evaluate risks in good time and to propose and implement suitable actions with the aim of improving products or processes and avoiding failure costs (recalls, yield).

FMEA helps prevent potential failures by systematically analyzing and documenting potential failures. Early and therefore preventive implementation of FMEA helps produce defect-free products and thus contributes to maintaining corporate success in the long run.

The Failure Mode and Effects Analysis method is a preventive technique for identifying, eliminating or mitigating potential causes of failure.

The Failure Mode and Effects Analysis method is a risk analysis method that aims to predict and eliminate errors in system, design, process and service issues before they occur, or at least to eliminate/reduce their effects.

Error prevention made easy: Leverage shop floor experience by using QAP FMEA in conjunction with QAP Audit, Process Control and Customer Complaints and Nonconformance Resolution Management modules.

The QAP FMEA module has been developed according to the new standards set in the Failure Mode and Effects Analysis FMEA Handbook published jointly by AIAG and VDA organizations.

Only a current and well-maintained Failure Mode and Effects Analysis (FMEA) is really efficient.